VACUUM 1 PNEUMATIC PELLET FEEDING SYSTEM allows pellet (sawdust granulate 6±1mm) feeding at large distance from the storage room directly to the boiler.

The pneumatic system consists of two flexible tubes and a pellet storage tank integrated with the boiler. The fuel is sucked from the storage room chamber by a suction turbine via the tube to the storage tank. The other tube returns the air to the storage room. The system prevents dust ingress into the boiler room.

The flexible tubes (blue and red) allow easy positioning of the main fuel tank. High efficiency allows fast refilling of a buffer tank used in normal boiler operation.

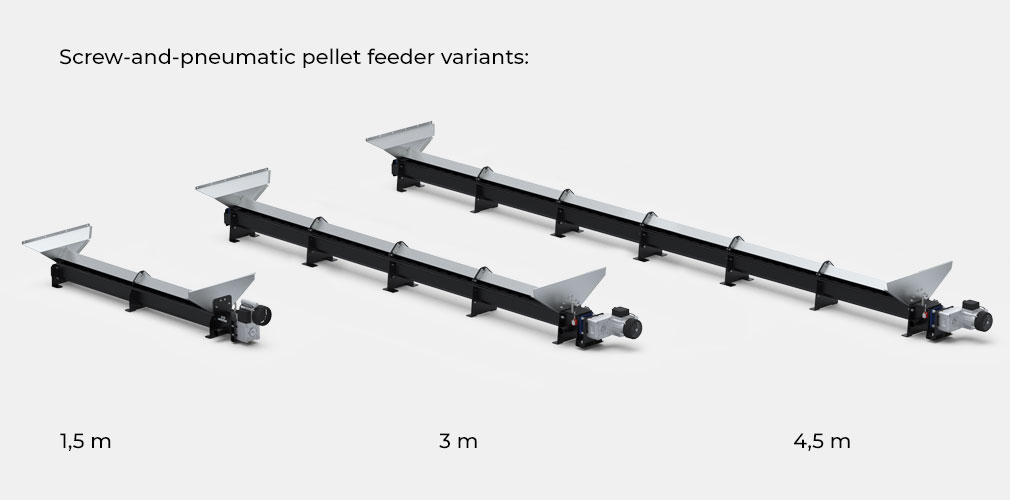

Capacity of pellet storage tank with the dimensions of: 3m (max. thickness of fuel layer) x 2m x 4.5m (feeder variant) is approx. 14 tonnes.