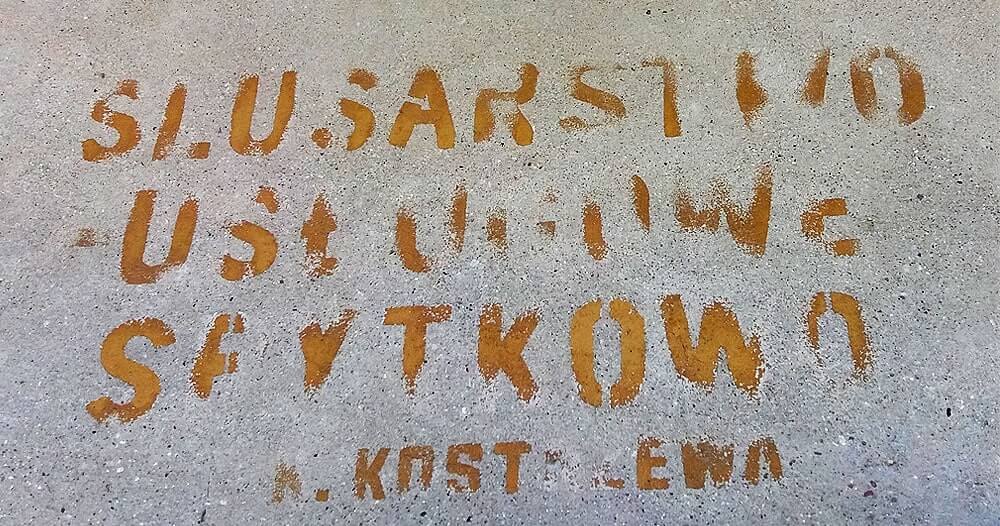

Kostrzewa's warmth for thousands of families

In the period between 2000 and 2017 Kostrzewa has made over 60 thousand pellet heating devices for single family homes, which means that they keep 300 thousand people warm. The company participated in 1000 large projects involving boilers with power up to 300 kW.

This motivates Kostrzewa to redouble its efforts and seek even better solutions, such as boilers with the innovative Platinum Bio VG variable geometry burner, adjusting the device's power to the current heat demand.

We are working on new ways to heat

In 2014 the company launched its own modern research laboratory. The research facility allows to test the designed devices for important parameters (efficiency, emissions, power consumption etc.) before they are delivered to our Clients. KOSTRZEWA's laboratory also works with several research facilities in Poland.

Practically maintenance free and cost effective, safe and low on emissions - all for the client's comfort and satisfaction. These are not promises, these are facts. They are guaranteed by, among other things, the meeting of the strict requirements of the so-called EU Ecodesign, confirmed by certified of accredited external laboratories. Certificates are important, but satisfied clients are even more important.

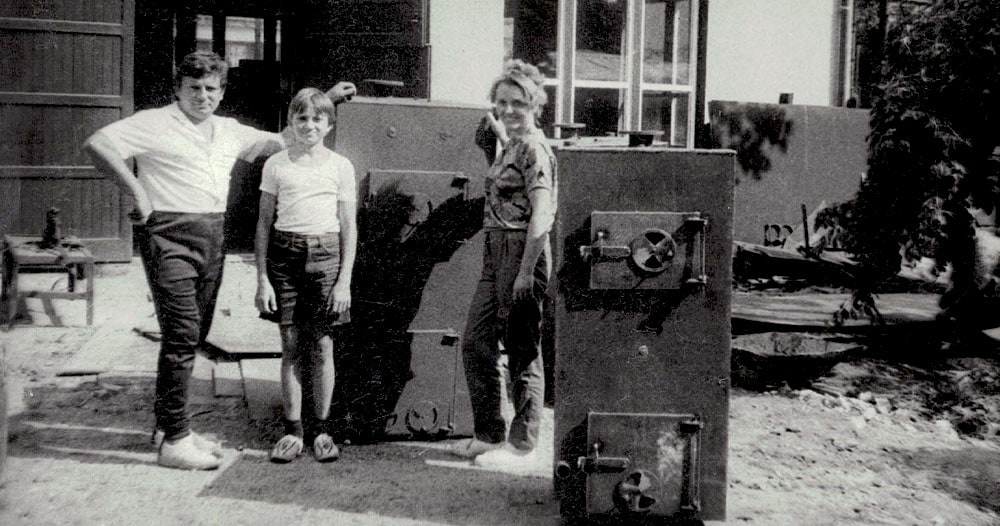

KOSTRZEWA has production and storage buildings with the total area of 15 140 m².

Currently, the factory of clean heat biomass devices is being significantly expanded.

At the same time, new technologies for producing heat from renewable energy are being developed.