MODERN DESIGN

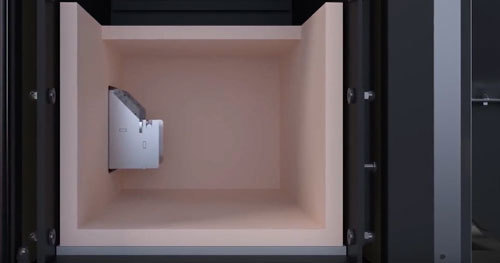

A modern boiler with an integrated burner, storage hopper and fuel feeder. Compact shape and small dimensions perfect for boiler rooms with limited space.

SAFETY

Twin Bio Luxury boiler features OMS for boiler and burner condition monitoring. When the controller receives information about any irregularities, the device is disabled and a message is displayed on the boiler controller or the weather compensator screen.

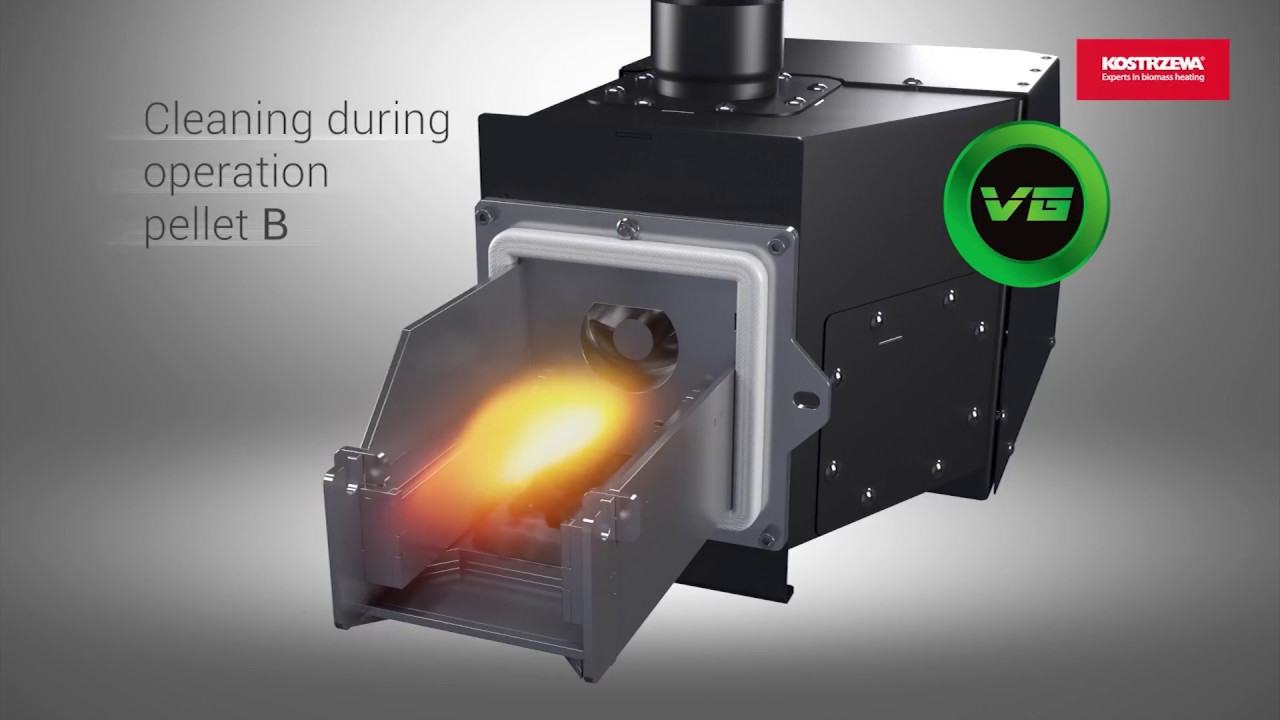

ECONOMY

Innovative Platinum Bio VG burner automatically adjust its parameters to the building’s heat demand by increasing or decreasing its size (variable burner grate length). The burner design uses a variable geometry (VG) technology. Patented in the Polish Patent Office.

EXTREMELY DURABLE

All our devices undergo a series of tests to verify the flow rates, strength and stresses followed by long-term strength tests in a laboratory.

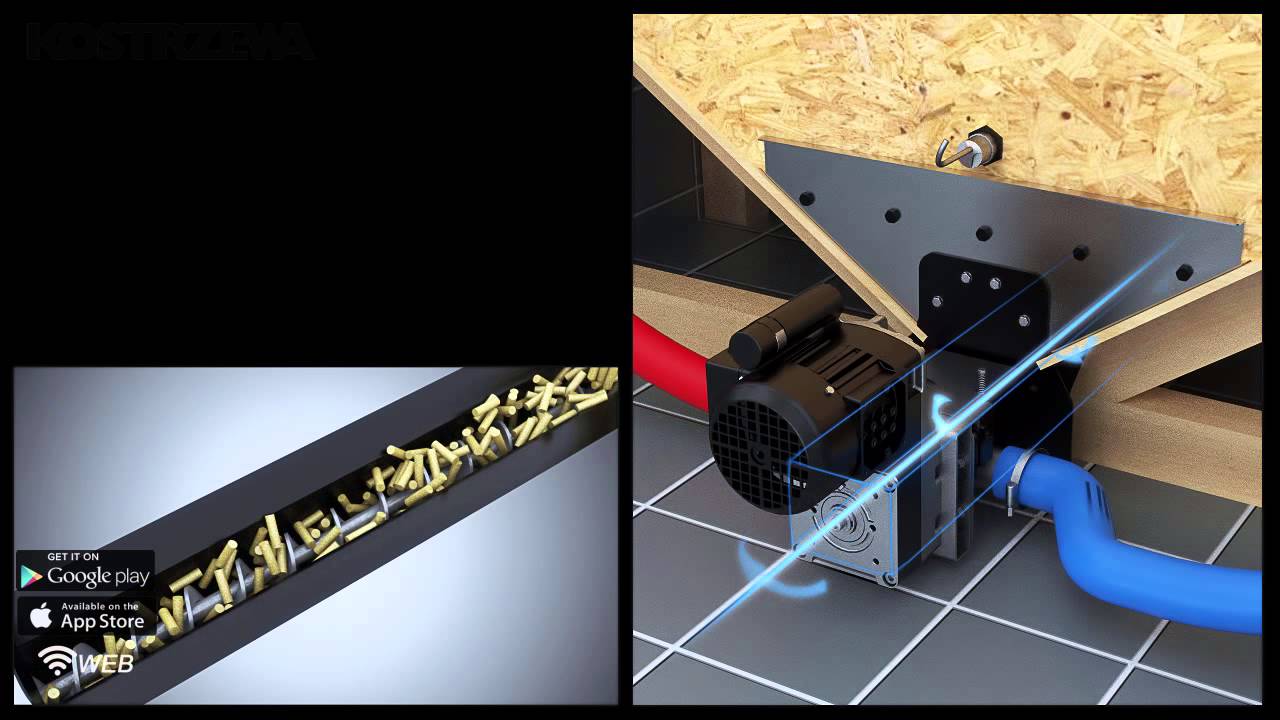

INTERNET MODULE

All boiler and central heating system functions can be remotely monitored using a PC or a smartphone (optional).

RELIABLE SERVICE

We maintain an extensive service network. Over 200 qualified service engineers provide warranty and post-warranty services in Poland and abroad.

A COMPLETE HEAT SOLUTION

Even the best boiler isn’t enough. We offer complete boiler room and heating system solutions. We offer advanced solutions including pellet storage, pneumatic fuel feeding, cascade automation, weather compensated CH system control, DHW and buffer tank control, return protection, fuel and ash sensors, heat pump, solar panel and gas boiler control.