If you did not find an answer to your question, please contact us by e-mail at faq@kostrzewa.com.pl

If you did not find an answer to your question, please contact us by e-mail at faq@kostrzewa.com.pl

Pellets is an ecological fuel made from sawdust - waste from wood processing industry - compacted under high pressure.

Significantly, pellets manufacturers use sawdust - leftovers from the manufacture of boards, furniture, and the like. Therefore, there is no need to cut trees to produce wood pellets - it simply suffices to manage the resulting waste.

Pellets is produced from unprocessed wood, void of binders. High-quality pellets does not contain any contaminants. There are three classes of pellets: A1, A2 and B.

Times change - it is no mere craze, but rather a natural course of events. Pellet was first produced in the Nordic countries, where there are no coal deposits. Both types of fuel have a common, plant origin. In case of pellet we deal with “fresh” wood, while in case of coal, it underwent an abundance of chemical transformations over the millions of years, which changed its appearance and properties.

The individual heating industry gradually moves away from the use of coal. In household conditions, pellets constitutes the cleaner and more convenient fuel.

Because it is worth to trust in our experience. We have specialized in the production of automatic pellet boilers since 2000 - for the longest time amongst all domestic manufacturers of this type of devices. Our designers have developed a variety of innovative technological solutions – the most important of them have been patented. External accredited laboratories confirm the high quality of our boilers (Eco-design EU certificate, class 5 certificate compliant with PN EN 303-5:2012 norm). We also have the most extensive biomass boiler service network in the industry. We offer a wide range of heating power – we offer equipment ranging from 8 kW to 330 kW, in different variants.

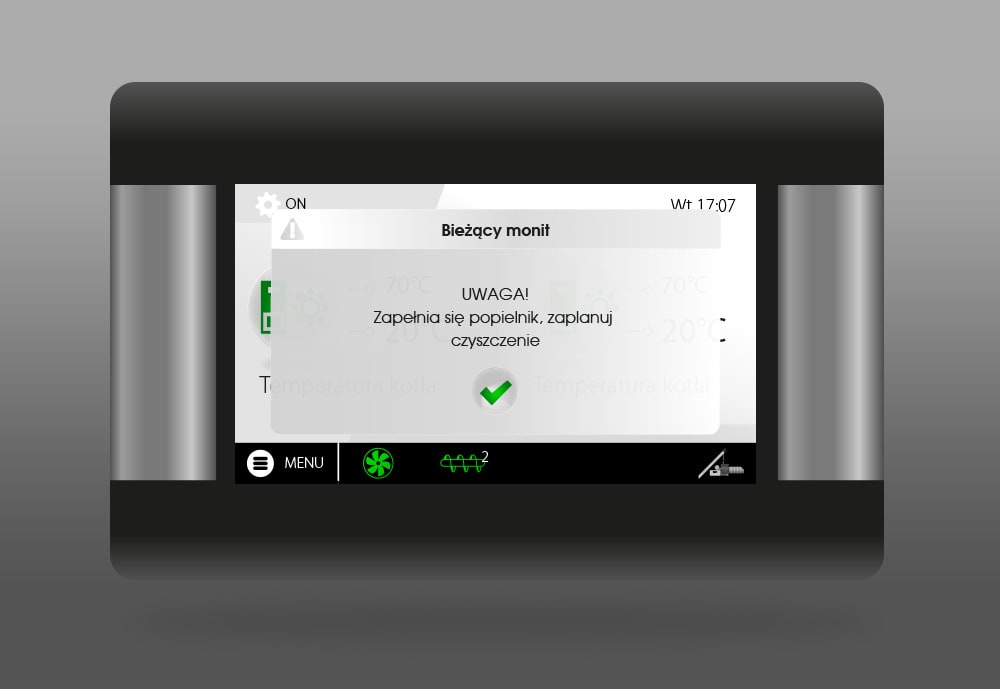

Depending on the model of the boiler, and the amount of fuel burned - once every 300-1,000 kg of pellets. In case of KOSTRZEWA boilers, you do not need to worry – the OMS system will remind you if there is such need. Following the heating season the frequency of removing the ash is extended to approx. 4-8 weeks. It is important to know that the ash content in pellets is approx. 0.5%, which means that burning of one ton of fuel produces approx. 5 kg of ash. For comparison - the use of coal produces approx. 100 kg of troublesome ash, which must be removed and subjected to waste management.

In such a case it is best to opt for a pneumatic fuel system with a large fuel tank that will ensure year-round charge. If a parent is physically fit, you can decide in favour of a smaller tank. Even if you run out of fuel and thus the equipment stops working - refuelling is enough to start the boiler anew. The automatic start is ensured by the OMS system.

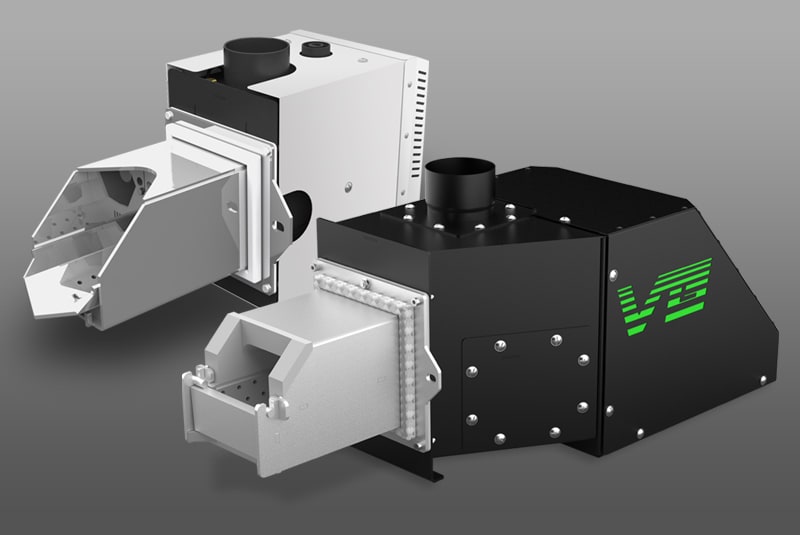

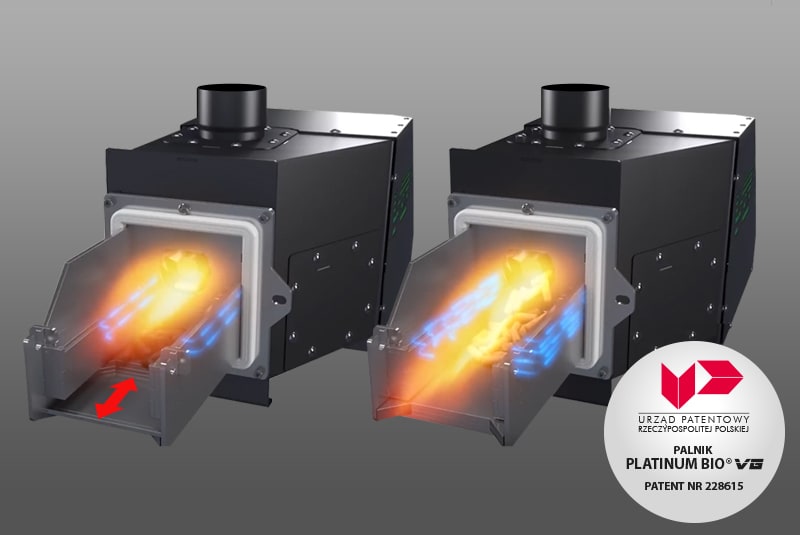

Both burners are dedicated to different quality fuels. If you use A1 pellets (highest quality fuel), then the cheapest, easiest and most reliable solution would be to use a central heating boiler with Platinum Bio burner. When using this device, the ash from the burner is collected by hand once the contents of the fuel tank burns-out. If you use fuel of varying quality, the optimal choice will be to use the VG burner - a device with variable geometry which allows to modify the grid dimensions and power, and thus most effectively use each dose of fuel. Each boiler with Platinum Bio VG burner is equipped with the OMS system that will remind you about the need to add fuel and clean the tank. The device adjusts its power to the building’s current heat demand and retains maximum efficiency at every power. The VG burner is equipped with mechanical cleaning, which allows you to remove sinter and operate with maximum efficiency.

Variable geometry can be compared to the functioning of wings in a jet. This is an innovation in the heating industry on a European scale, the solution has been patented in the Patent Office of the Republic of Poland. In case of a drop in heat demand, the entire hearth is not aerated, but only the part where the fuel is located. While working, the burner changes its volume by modulating the grid dimensions.

We invite you to watch a film presenting the functioning of VG burner:

Ash has a mineral composition that has a favourable impact on soil and is safe for the environment, thus it can be used as a fertilizer. Once it cools down, you can use it to fertilize your garden.

Thanks to the use of pellets, our chances to eliminate smog grow. While burning pellet in automatic boilers from KOSTRZEWA, minimum amount of pollution is formed (pellet, as opposed to coal, practically contains no sulfur, and minimal amounts of dust are emitted during combustion).

The device requires minimum involvement, because it works in an automatic mode. The only work you have to do is to fill the fuel tank, empty the ash and occasionally clean the equipment. Sensors will inform you about everything - the ash needs to be removed after burning approx. 400-1,000 kg of fuel. One tank, depending on the heat demand, can last even for a month. At lower temperatures, it lasts for about a week.

Pellets are available in handy 15 kg bags. Another option is the “big-bag” weighing 1 ton. The fuel can also be purchased in bulk, delivered by tank truck or dump truck.

Pellet boilers are a good solution for anyone looking for a convenient and low-cost heating system to be applied in a newly constructed home, as well as existing buildings, where the aim is to reduce heating costs. Besides economic advantages and convenience, it is essential that such heating emits negligible amounts of pollution and thus help take care of our health. You can negotiate the price with every vendor. It is worth to buy the fuel during summer.

One of the solutions is either to modernize the boiler by installing a new burner to an existing boiler or replace the entire boiler. It is worth replacing the burner in a modern oil boiler or solid fuel. When dealing with a worn-out and obsolete equipment, it is much better to invest in a new one.

Such a scenario is unlikely because the domestic production of pellets is growing steadily. In 2017, Polish companies produced more than one million tons of pellets. Currently, a significant proportion of this fuel is destined for export - reduction of VAT on this fuel would certainly retain part of the production in the country.

You can apply a pneumatic fuel feed system, which transports the pellets from an external, high-volume tank to the boiler room. Thanks to this solution, you can provide a year-round fuel charge.

We invite you to watch an animation showing the administration of pellets with the participation of PELLETS VACUUM air feeder from KOSTRZEWA:

If you use pellets fuel – then yes. The boiler room is clean and has the smell of wood. There is no such possibility in case of burning coal peas.

Basically, you should burn less eco-pea coal than pellets, because coal is a more caloric fuel. In practice, however, it is different. The average useful efficiency of pellet devices is much higher compared to pea coal equipment. In view of the fact that a pellet boiler works only in case of heat demand, and an eco-pea coal boiler works in a continuous mode, you consume similar quantities of fuel. In houses with good thermal insulation you need approx. 5 tons of fuel per year. Some of our customers are of the opinion that pellet is more economical compared to eco-pea coal.

In laboratory conditions, both indicate similar efficiency. In household conditions, in view of the fact that pellet boilers are equipped with a function of automatic ignition and quenching, their average efficiency is much higher thus resulting in lower fuel consumption. The key issue is the ability to maximize the energy contained in the fuel, which depends on the design of both the boiler and burner. The efficiency of both types of devices is similar. Nonetheless, customers, who managed to compare the fuel consumption after replacing a pea coal boiler pea with a pellet boiler, stated that the quantitative fuel consumption is the same or even smaller.

It is definitely easier to adjust a pellet boiler due to smaller fuel contamination. Pellet is a standardized means of fuel characterized by smaller deviations in terms of quality compared to coal, it is much cleaner, has lower humidity, its granulation was standardized (6 mm or 8 mm). In case of pea coal, the ash content within the fuel can amount up to 12% (pellet approx. 0.5%). All of this affects the adjustment of the combustion process in the boiler.

Yes. In boilers not equipped with automatic cleaning of the heat exchanger, you should do it once every 3 months. It is worth to buy a vacuum cleaner to clean the heat exchanger. Cleaning takes max. 10-15 minutes.

For economic reasons, this should be done when the temperature reaches 150°C.

You must set a higher temperature in the room regulator. “Yes” means that there is a need to heat the rooms, while “no” means that there is no such need, because the temperature has been reached.

If the return temperature is 45 degrees, it should not cause any problems. The boiler is designed to work in temperature ranging from 50 to 80°C and functioning at such temperatures is not harmful. There is one condition that must be met, so that you do not have to worry about the wear of the heat exchanger. The installer must connect the boiler properly with the use of components preventing the return of cold water (temperature lower than 45°C) to the boiler, which could cause premature wear of the heat exchanger.

Many factors affect the selection of a chimney. A designer should take care of the selection should. In the design guidelines of aerial and internal-combustion installations it is written that the chimney should be insensitive to moisture due to the possibility of water vapour condensation. Furthermore, the diameter-to-height ratio is selected depending on the climatic conditions, so that the chimney is able to collect exhaust gases from the boiler. It is important that the chimney supports the combustion process, thus it must generate flow (vacuum), which is different for different power boilers. Small boilers up to 20 kW should have a flow of at least 15 Pa.

Few chimney sweeper companies are able to measure the flow, as they have wind gauges at their disposal that measure flow but not vacuum.

Each change in the type of pellet to another is followed by the need to regulate the functioning of the burner. You must make fuel weighing anew, enter the calorific value of used pellets, and then analyse the combustion process with the use of an exhaust analyser.

Due to various bulk density of pellets and pollination of this fuel, it may be necessary to readjust the sensitivity of the fuel level sensor. Kostrzewa company provides a screwdriver for adjusting the fuel level sensor along with the boiler. If there is a situation where the controller signals a low level of pellets, and the tank is even 3/4 full, then use a screwdriver to turn the adjustment screw to the right until the light sensor lights up. If the regulation will yield no effect, please contact our customer service.

Please use high-temperature silicone.

If the day-time temperature is maintained at 22.5°C, the night temperature should be maintained at a given level as well. Perhaps the building is properly insulated and maintains warmth, hence the room temperature maintains at the level of 21.8°C for a long time. Make sure that the time zone is set on the room regulator, or perform a test by manually turning off the boiler at a specific time and turning it on only upon the morning. If the effect is similar, you must plan an economic mode in advance. In case the effect is quite different - the temperature drops to the preset 16°C - please contact the Service Department that commissioned the device.

Boiler Pellets Plus 25 kW meets the requirements of class 4 according to PN EN 303-5: 2012. You have time until 2026 to replace your equipment for newer one, compliant with the requirements EU ecodesign.