LOW PELLET AND ENERGY CONSUMPTION

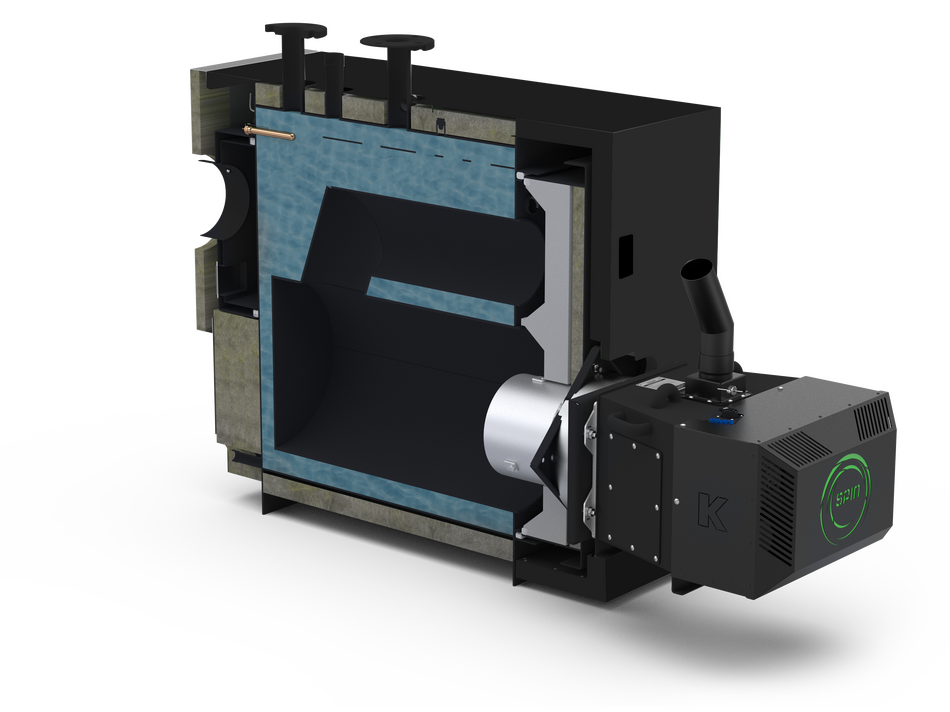

This is the main goal of our designers. No other boiler available in Poland is as efficient. Compact heat exchanger, efficient water jacket and thermal insulation guarantee the highest efficiency. A combustion process monitored by the oxygen sensor and Fuzzy Logic 2 controller guarantees the lowest emission and fuel consumption.

MANY YEARS OF FAILURE-FREE OPERATION

Highest quality materials and components by renown manufacturers guarantee the highest reliability of our boilers. Regular maintenance and annual inspections guarantee failure-free operation for over a dozen years.

DURABLE

Our boilers guarantee failure-free operation for many years. High quality steel and the highest quality components. All our boilers are individually tested for durability at min. 6 bar - a feature hardly ever found elsewhere.

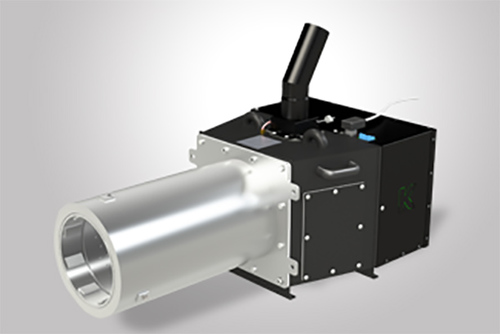

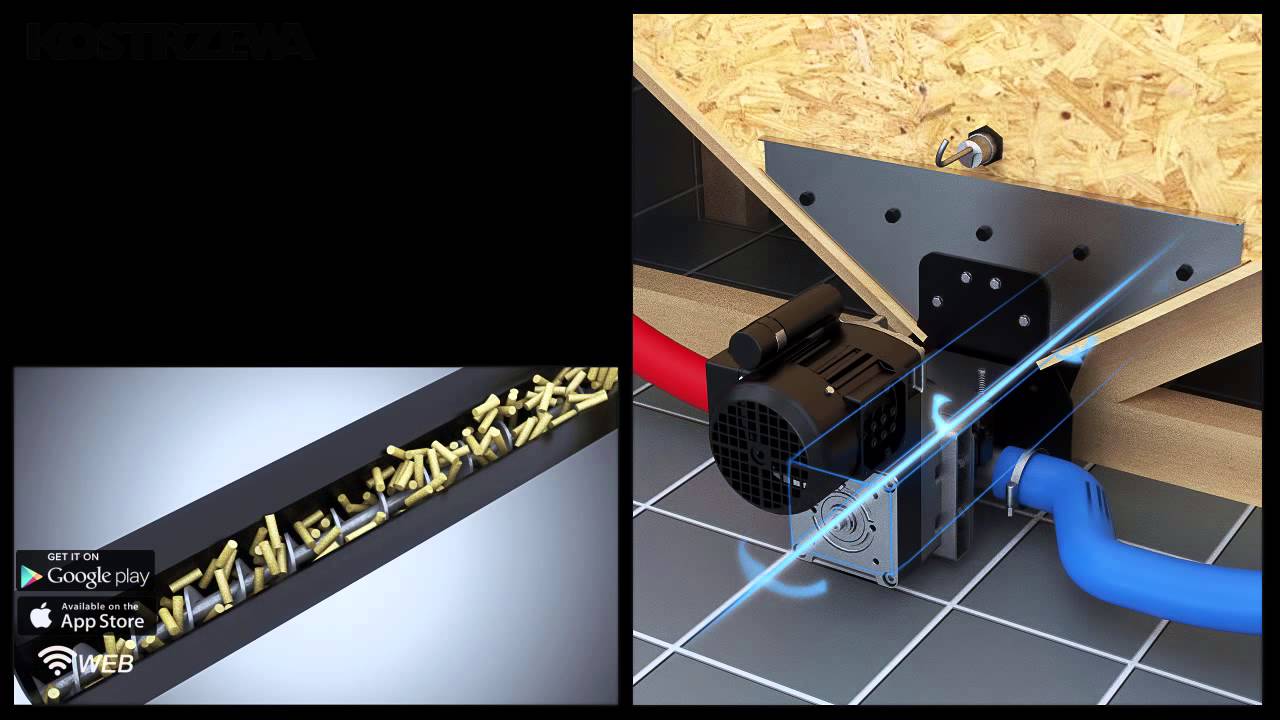

SELF-CLEANING BURNER

Innovative rotary PLATINUM BIO SPIN burner guarantees maintenance-free combustion of class A1, A2 and B wood pellets. The technology used allows to purchase pellet up to 50% cheaper than available for owners of other boilers (usually more expensive class A1 pellets).

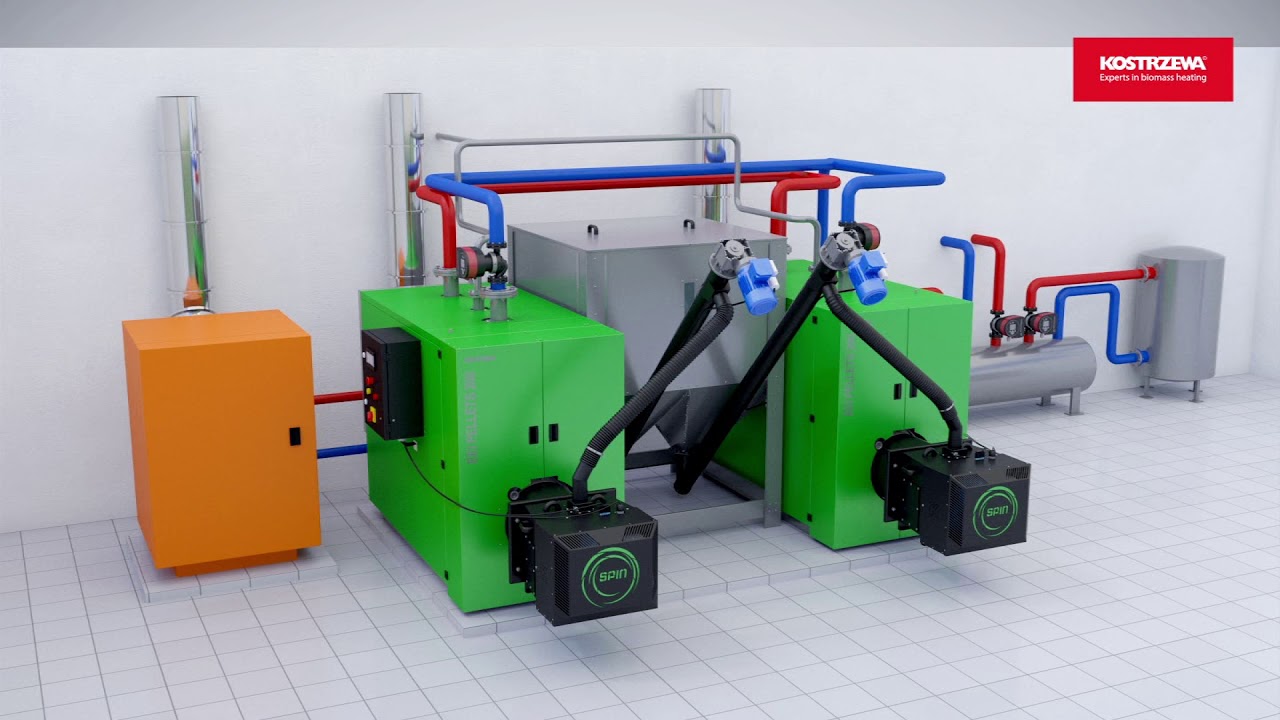

COMPLETE HEAT SOLUTION

Even the best boiler isn’t enough. We offer complete boiler room and heating system solutions. We offer advanced solutions including pellet storage, pneumatic fuel feeding, cascade automation, weather compensated CH system control, DHW and buffer tank control, return protection, fuel and ash sensors, heat pump, solar panel and gas boiler control.