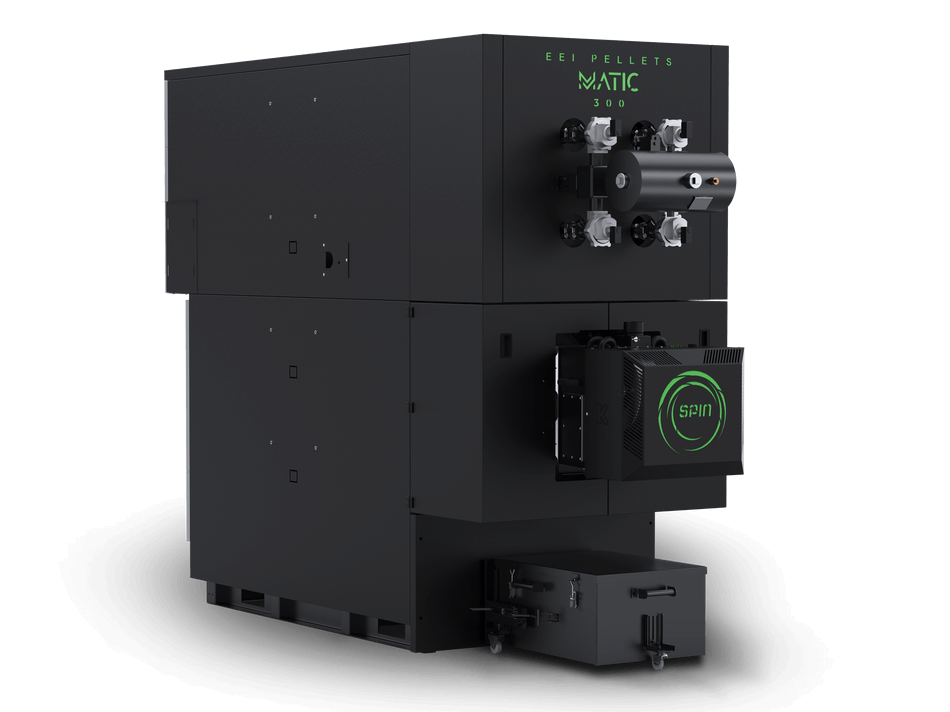

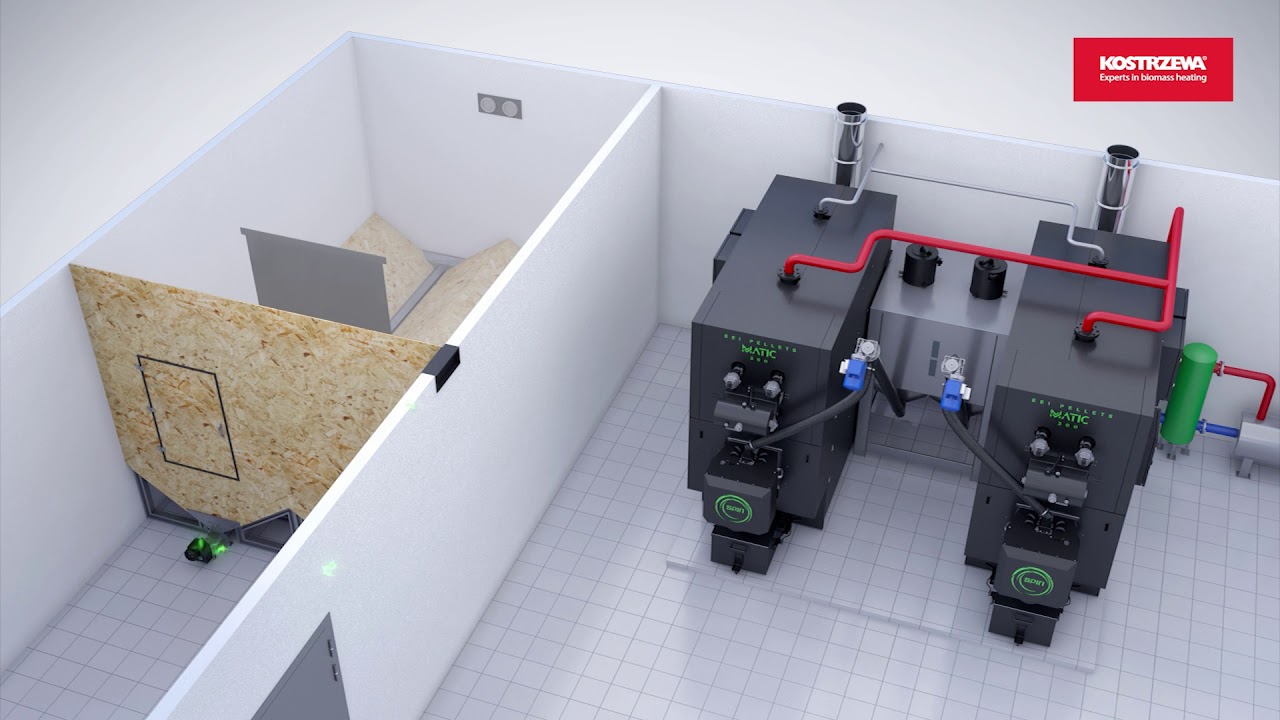

AUTOMATIC OPERATION AND CLEANING

Operating a pellet boiler can be even more convenient. Automated boiler operation processes limit the manual operations to a minimum. Apart from the functions available in EEI PELLETS model, the MATIC version includes pneumatic heat exchanger cleaning and automatic ash removal from the ash pan.

LOW PELLET AND ENERGY CONSUMPTION

Attention to the greatest convenience combined with low pellet and energy consumption. Energy efficiency is verified by the test results by the Accredited Research Laboratory. The highest performance is achieved by optimum use of all heating surfaces, including heat recovery from the ash. The boiler is thermally insulated and the combustion is controlled by a proprietary OMS PRO operating system supported by an oxygen sensor to set the optimum combustion and boiler operation parameters.

MANY YEARS OF TROUBLE FREE OPERATION

The quality of materials used guarantees many years of operation at the highest efficiency. Every single component is carefully selected by KOSTRZEWA design department. Most of the boiler components are manufactured by KOSTRZEWA. The cleaning systems and the ash separator (ash from pellet grades other than A1 may contain more residue) guarantee trouble free operation.

DURABLE

Our boilers guarantee failure-free operation for many years. High quality steel and the highest quality components. All our boilers are individually tested for durability at min. 6 bar - a feature hardly ever found elsewhere.

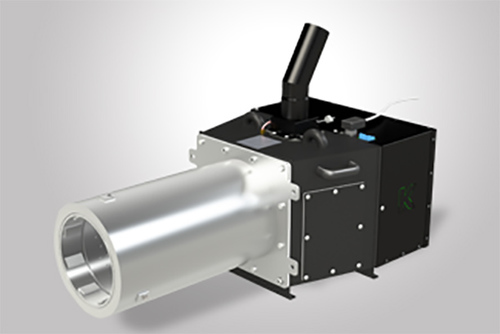

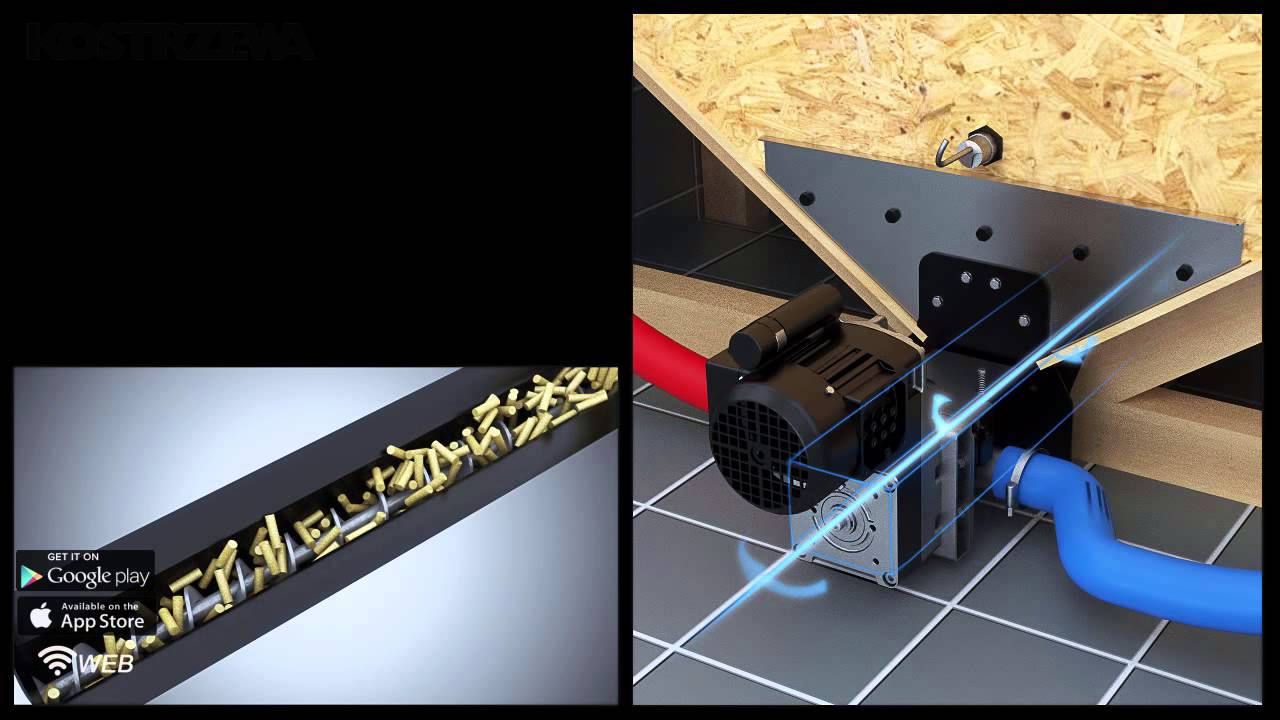

SELF-CLEANING BURNER

Innovative rotary PLATINUM BIO SPIN burner guarantees maintenance-free combustion of class A1, A2 and B wood pellets. The technology used allows to purchase pellet up to 50% cheaper than available for owners of other boilers (usually more expensive class A1 pellets).

COMPLETE HEAT SOLUTION

Even the best boiler isn’t enough. We offer complete boiler room and heating system solutions. We offer advanced solutions including pellet storage, pneumatic fuel feeding, cascade automation, weather compensated CH system control, DHW and buffer tank control, return protection, fuel and ash sensors, heat pump, solar panel and gas boiler control.