AUTOMATIC OPERATION AND CLEANING

The buildings can be automatically heated with air with full control and programming via the Internet. Automatic burner, ash pan cleaning, output adjustment based on outdoor and indoor temperatures provide comfortable use and conditions in the building.

LOW PELLET AND ENERGY CONSUMPTION

Many buildings require periodical or time-based heating - our forced-air heating systems can be used as and when necessary. Any area can be heated from 0°C to several degrees Celsius in less than an hour. The transfer of heat to the surrounding area is practically immediate and does not generate any losses for heating and distribution of large volumes of water. The system also eliminates risk of freezing. Our forced-air systems feature microprocessor-controlled fans and offer very low energy consumption.

MANY YEARS OF TROUBLE-FREE OPERATION

The quality of materials used guarantee many years of operation at the highest efficiency. Every single component is carefully selected by the KOSTRZEWA design department. The majority of system components is manufactured by KOSTRZEWA.

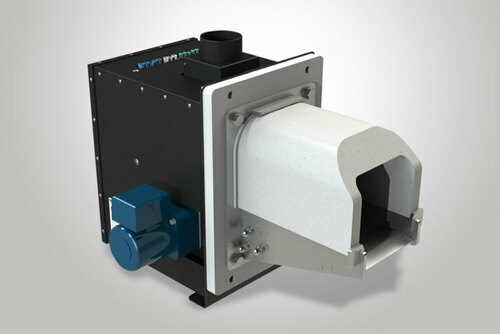

ROBUST DESIGN

In modern production of heating devices, the key factors include automation and repeatability of production processes and high quality of steel and construction methods used. The air heaters can reach air temperatures up to 70°C without any deterioration in quality.

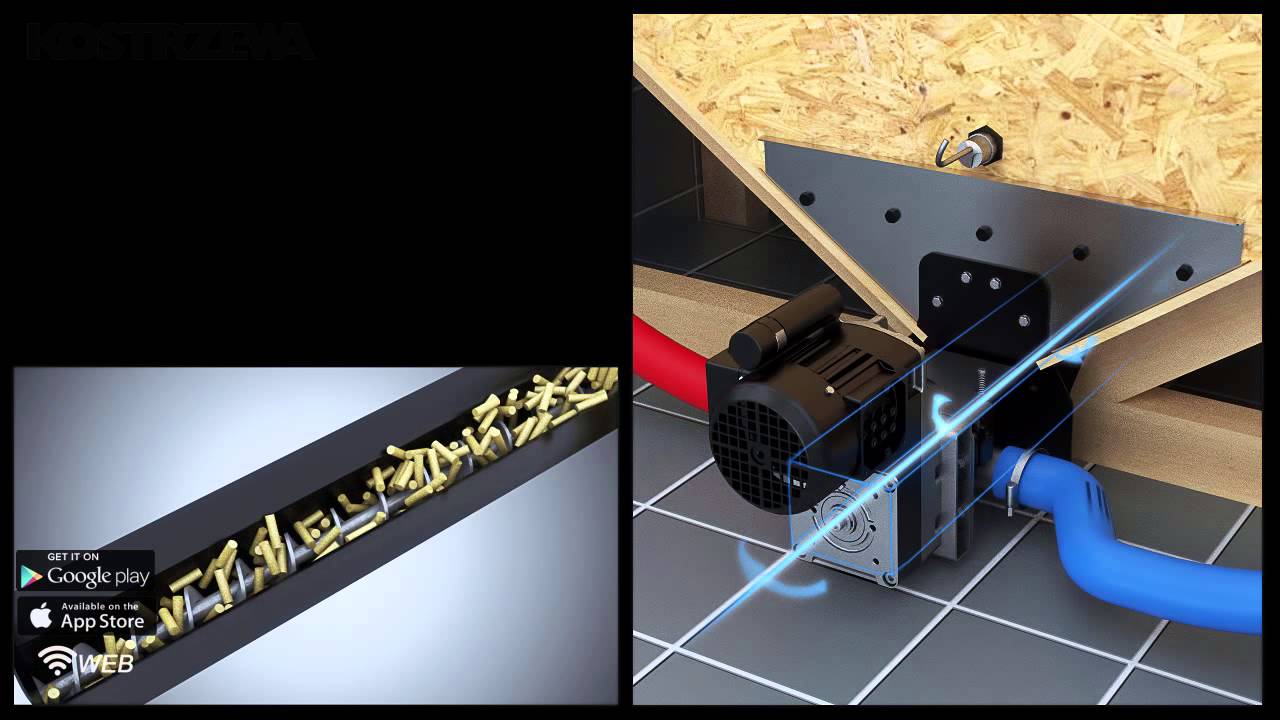

SELF-CLEANING BURNER

Innovative rotary PLATINUM BIO SPIN burner guarantees maintenance-free combustion of class A1, A2 and B wood pellet. The technology used allows to purchase pellet 50% cheaper than pellet available for users of other forced-air heating systems that usually require more expensive class A1 fuels.

A COMPLETE HEAT SOLUTION

We offer comprehensive heating solutions for any building, including our pellet storage systems, pneumatic pellet feeders, cascade control systems, weather compensation, fuel and ash level sensors. Forced-air heating can operate in a closed loop, mixing the warm air inside the building with the fresh outside air.