IMPROVING ON THE ICONIC MINI BIO

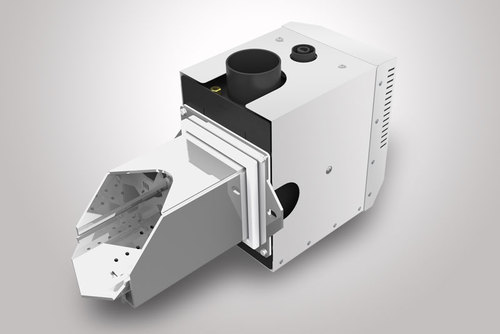

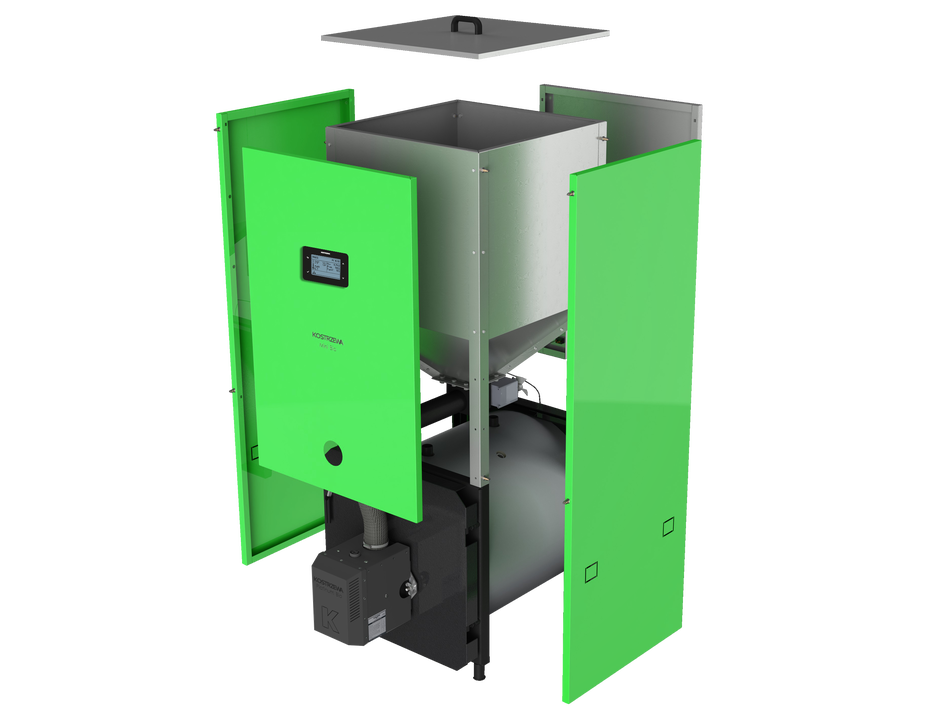

Designed for heating buildings without boiler room or with small boiler room. Reduced overall dimensions with a storage hopper installed on the heat exchanger - a solution used for the first time by Kostrzewa in 2009 in our flagship product Mini Bio boiler and well-received by our clients. A new version with improved comfort, cleanliness and a guaranteed energy-efficiency.

SIMPLE AND CONVENIENT

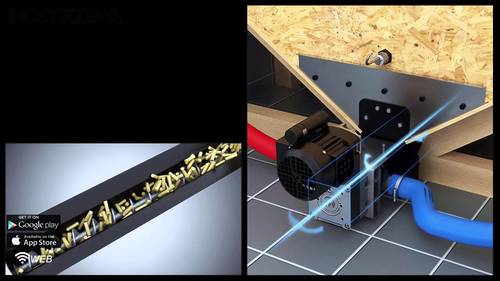

The OMS (Operating and Monitoring System) monitors fuel level and ash content. User is informed in advance that the fuel storage must be refilled or the ash pan requires cleaning.

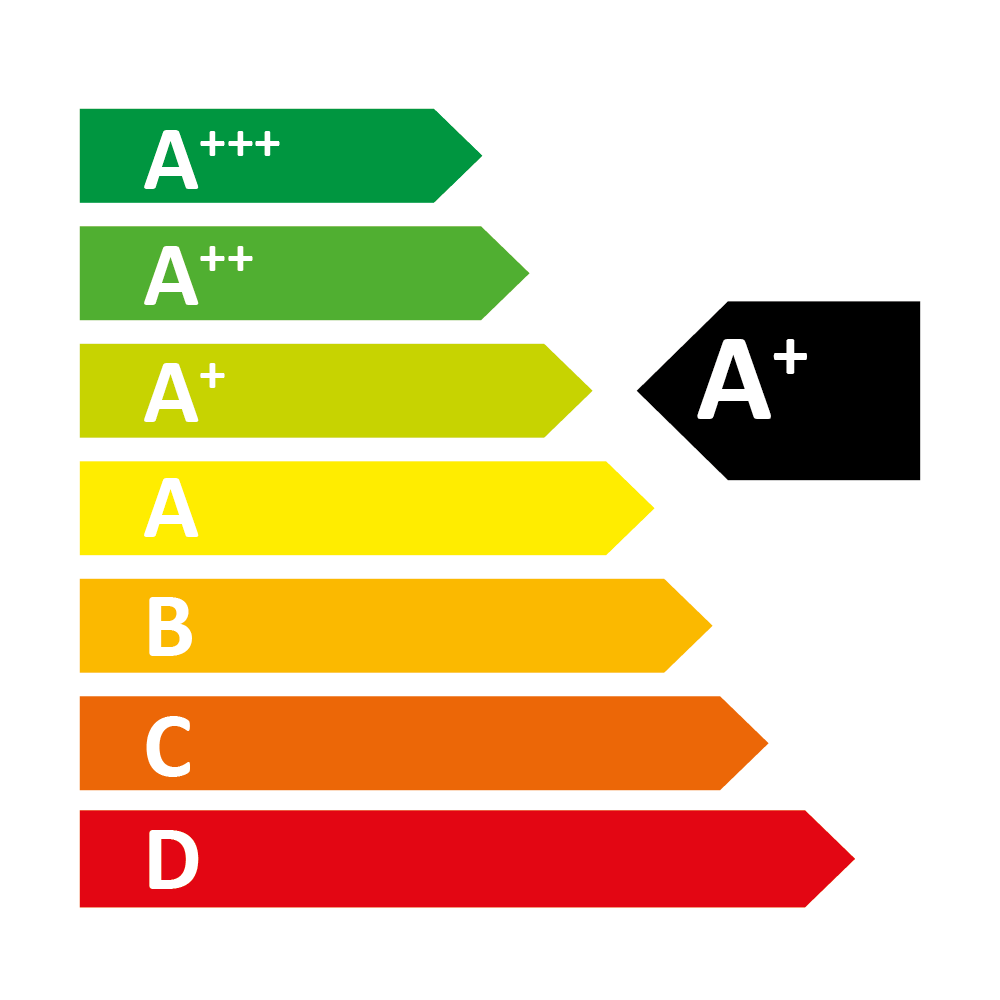

LOW FUEL USE

Reduced fuel consumption with Mini Bio. A unique design and advanced ceramic inserts for over 90% efficiency.

DURABILITY

High quality steel and the highest quality components guarantee many years of failure free operation. All new models are thoroughly tested for many months before marketing. All our boilers are individually tested for durability at min. 4 bar - a feature hardly ever found elsewhere.

RELIABLE SERVICE

We maintain an extensive service network. Over 200 qualified service engineers provide warranty and post-warranty services in Poland and abroad.

INTERNET MODULE

All boiler and central heating system functions can be remotely monitored using a PC or a smartphone (optional).

COMPLETE HEAT SOLUTION

Even the best boiler isn’t enough. We offer complete boiler room and heating system solutions. We offer advanced solutions including pellet storage, pneumatic fuel feeding, cascade automation, weather compensated CH system control, DHW and buffer tank control, return protection, fuel and ash sensors, heat pump, solar panel and gas boiler control.