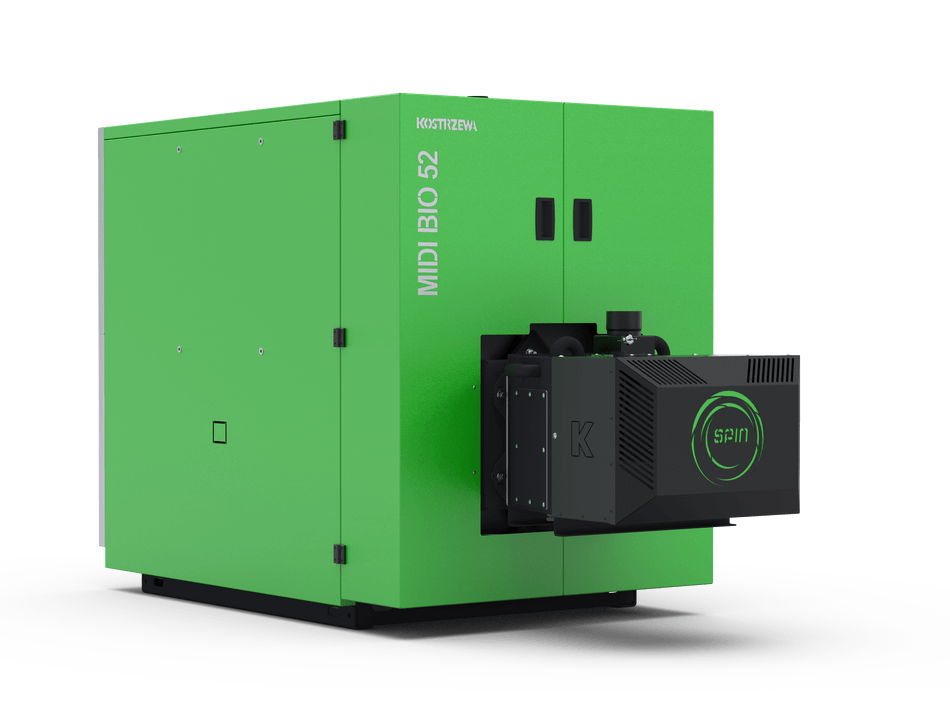

HIGH EFFICIENCY AT A GREAT PRICE

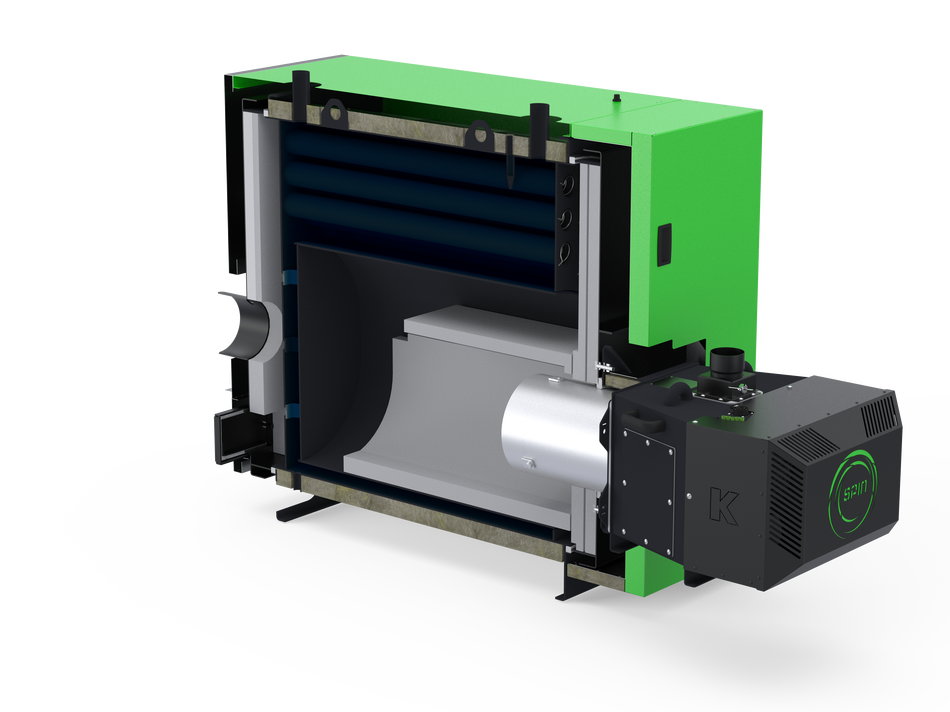

Our new boiler is an efficient and eco-friendly solution designed for large apartment buildings and industrial facilities. The boiler heat exchanger features a ceramic chamber for high fuel economy, lower emission and higher efficiency and flue gas vortex generators retaining energy inside the boiler.

MANY YEARS OF FAILURE-FREE OPERATION

Highest quality materials and components by renown manufacturers guarantee the highest reliability of our boilers. Regular maintenance and annual inspections guarantee failure-free operation for over a dozen years.

RUN AND FORGET

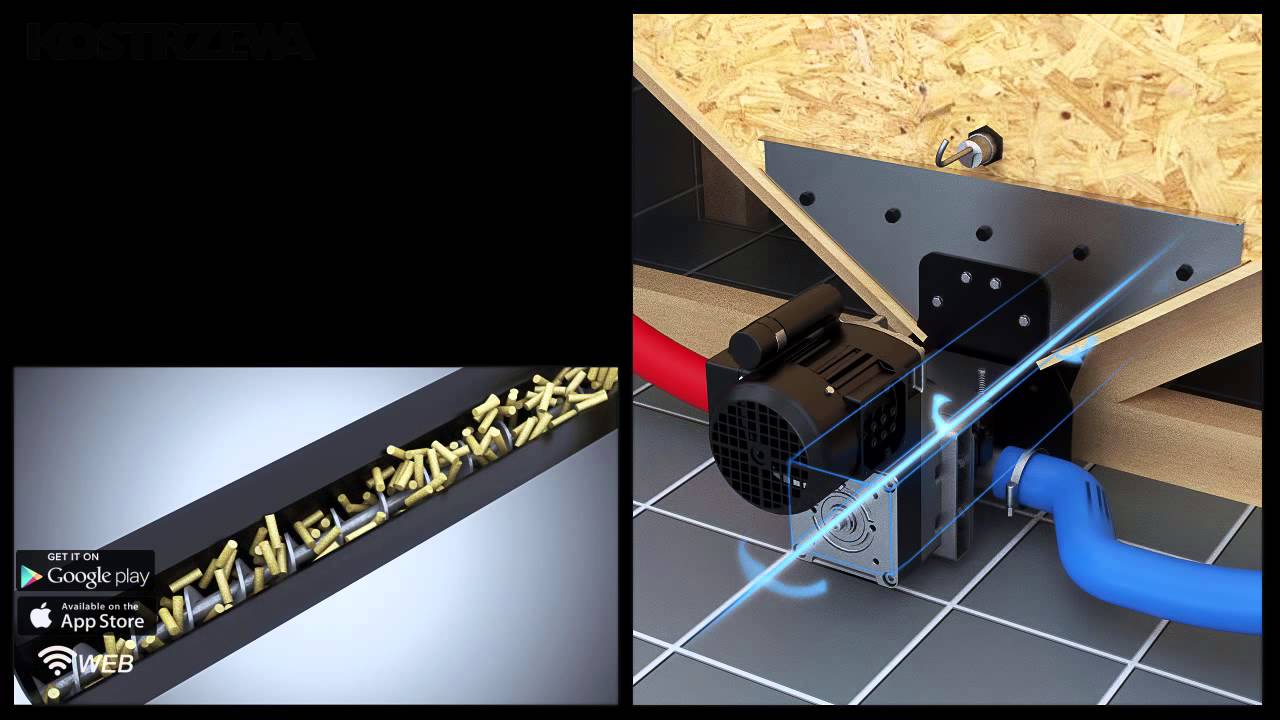

Our boilers are virtually maintenance-free to guarantee the highest comfort of operation. Automatic boiler start-up and shut-down with fuel level and ash content monitoring and notification in advance when fuel refilling or ash pan cleaning is required (OMS System). The number of visits to the boiler room can be kept to a minimum.

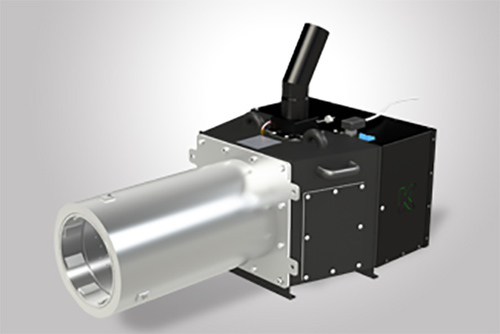

SELF-CLEANING BURNER

Innovative rotary PLATINUM BIO SPIN burner guarantees maintenance-free combustion of class A1, A2 and B wood pellets. The technology used allows to purchase pellet up to 50% cheaper than available for owners of other boilers (usually more expensive class A1 pellets).

INTERNET MODULE

All boiler and central heating system functions can be remotely monitored using a PC or a smartphone (optional).

RELIABLE SERVICE

We maintain an extensive service network. Over 200 qualified service engineers provide warranty and post-warranty services in Poland and abroad. Service can be arranged using our internet platform at www.serwis.kostrzewa.com.pl.

COMPLETE HEAT SOLUTION

Even the best boiler isn’t enough. We offer complete boiler room and heating system solutions. We offer advanced solutions including pellet storage, pneumatic fuel feeding, cascade automation, weather compensated CH system control, DHW and buffer tank control, return protection, fuel and ash sensors, heat pump, solar panel and gas boiler control.